With over 1 million square meters of real estate, Storebrand is one of Norway’s largest real estate managers. This also gives them a major responsibility. We had a chat with the sustainability manager in Real Estate, Unn Hofstad, about the industry’s joint climate responsibility.

If you could choose, would you prefer a shopping center with a water park, or a green city district with sustainable housing and great city living? In Økern, an area in eastern Oslo, there is a tall building that stands as a lonely landmark in an asphalt jungle of roads. Soon it can become an historical element in Oslo’s new district: Økern Centre. The district is going to take the world by storm – environmentally.

“Økern Centre will deliver the highest level of sustainable urban development, with a focus on the circular economy,” says Unn Hofstad, sustainability manager at Storebrand Eiendom.

We met her at Storebrand’s office at Lysaker in Oslo. Behind the office building, the beehives are ready and waiting for spring and new bees. When the building was completely rehabilitated 10 years ago, the goals were an excellent indoor environment and low environmental impact. Art from all over the world adorns the walls.

“Everything that is delivered in the Økern Centre project must be future-oriented. As one of the developers, it is our and my responsibility to set clear sustainability requirements for contractors, partners, suppliers and subcontractors.”

In fact, back in time Økern was planned to become a giant shopping mall with a water park, which was scrapped in the summer of 2019. Storebrand is developing the area with the retail giant Steen & Strøm.

Major responsibility

The goal of being one of Europe’s best in the sustainable management of real estate investments gives Storebrand a unique position to influence society. Unn’s job, greatly simplified, is to make the company so demanding on sustainability that it will have an effect in other industries as well.

“That we as a developer can set requirements gives us a responsibility. We must set specific sustainability goals in each project, and work out the environmentally sound solutions down to the last detail,” she says.

Unn speaks with both commitment and vision. She has great faith in the new district of Økern, and the work she does in Storebrand.

“Through many smaller initiatives, and not least large urban development projects, we have a key role in creating the climate-friendly city. We want to be part of the solution for a more sustainable society,” says Unn.

As one of Norway’s largest real estate managers, Storebrand can require fossil-free construction sites, solutions for dismantling and reusing building materials, green roofs to process run-off water and support biodiversity, and can establish green energy production. They may also require the use of building products and materials with low greenhouse gas emissions and free from substances that are hazardous to health or the environment.

Shape the future

Unn’s commitment to sustainability comes from a desire to contribute. As part of Storebrand, she can help shape the future.

“When Storebrand aims to generate a return on people’s pensions and savings, we set strict requirements for sustainability in the companies in which we invest. When we invest directly in real estate, things look a little different. As managers of real estate investments, we work very specifically with sustainability and the environment. Every day we make choices and decisions that can help make the world around us a little greener. We measure the properties’ environmental and climate footprint, certify the buildings based on sustainability, and work continuously to improve them,” explains Unn.

She continues, “This isn’t done in a day. Nevertheless, so many knowledgeable suppliers and new products and solutions are emerging in the market, that we as a developer now have a far greater opportunity to develop sustainable buildings and communities.”

To measure how environmentally friendly their buildings are, Storebrand uses the BREEAM certification program (Building Research Establishment Environmental Assessment Method). In the BREEAM system, buildings and areas are awarded a grade of Pass, Good, Very Good, Excellent or Outstanding. Storebrand aims to achieve a BREEAM grade of Excellent on its buildings.

Enthusiastic: As part of Storebrand, Unn can help shape the future.

One hundred percent reuse

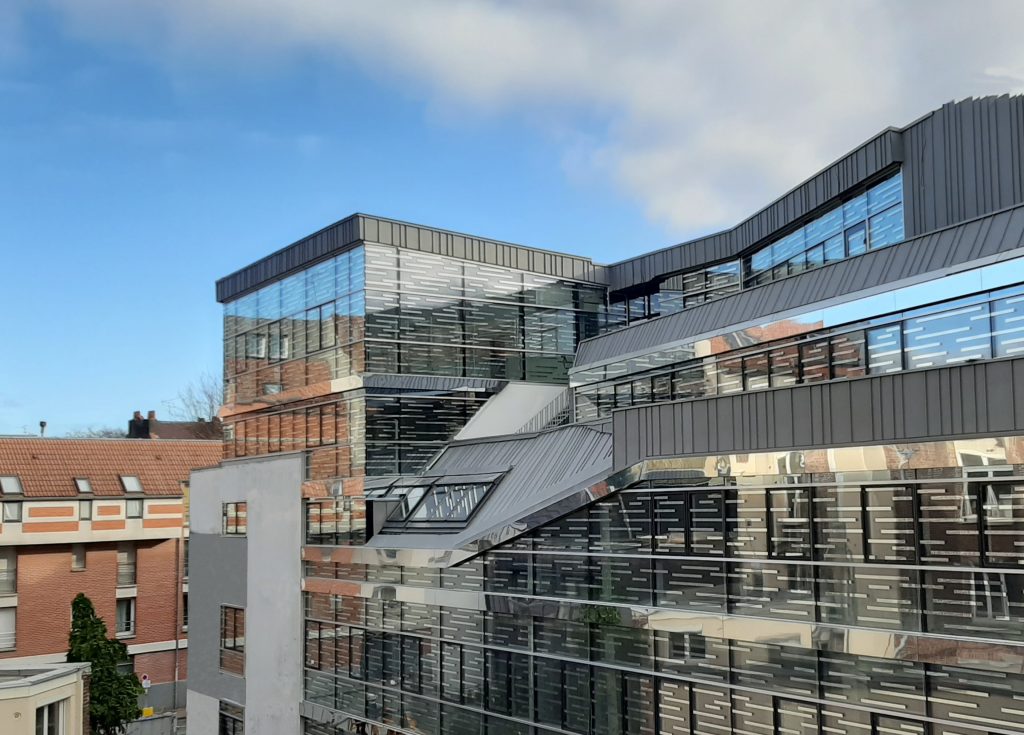

If you take the trip to Nydalen in northern Oslo you see by the subway station two slightly outdated office buildings. They stare down at the economists newly graduated from the Norwegian Business School BI, who rush by with sustainability on their minds. A few years ago, the buildings might have been demolished and rebuilt. Today, however, Storebrand examines very carefully the possibilities of re-using existing buildings when developing real estate. Finding the circular solutions is one of the biggest challenges for sustainable the real estate industry going forward.

“The goal of the development project is a large reduction in greenhouse gas emissions and 100 percent reuse. If we have to remove materials, we must reuse as much as possible. ‘New’ materials added should preferably be recycled, and at minimum reusable or recyclable,” explains Unn.

“Climate-effective products such as low carbon concrete and recycled metals are crucial, both in building construction and facade materials. Only five years ago, there was little access to recycled materials that could document greenhouse gas emissions from a life cycle perspective.”

Unn mentions aluminium as a good example of the shift that has taken place within the supply of greener materials. The metal is lightweight and can help realize exciting architecture. It can also be recycled indefinitely, with only four percent of the energy it takes to produce new aluminium.

“Developing these types of materials with good documentation is crucial to enable us to make the necessary calculations and sound, climate-friendly choices,” she explains.

Unn looks forward to the next steps.

“Recycled materials are just one of the pieces of the puzzle, but at the same time absolutely crucial. Now that we’ve got the first proof that it’s entirely possible to create environmentally friendly buildings and neighborhoods, it will be even more exciting to work on this in the future.”